- #Repetier server printer settings how to#

- #Repetier server printer settings manual#

- #Repetier server printer settings download#

Set the maximum Z speed in the settings to a reasonable value.Some versions had very slow z movement there's a fix for that:.Has default profiles for several different filaments.Has default profiles for Q5, QQ-S (Pro).Cura (opens new window) (open source available for PC, Mac, and Linux).This list only highlights the most popular Slicer choices!

#Repetier server printer settings download#

You should probably download the current version instead of using the provided one. You can use a design that provides a top and bottom for a piece of stiff but flexible material (there are several on Thingiverse).

So if you put flat sides on you'll limit the print area. When printing at the edge of the bed, the effector sticks out past the frame.

#Repetier server printer settings manual#

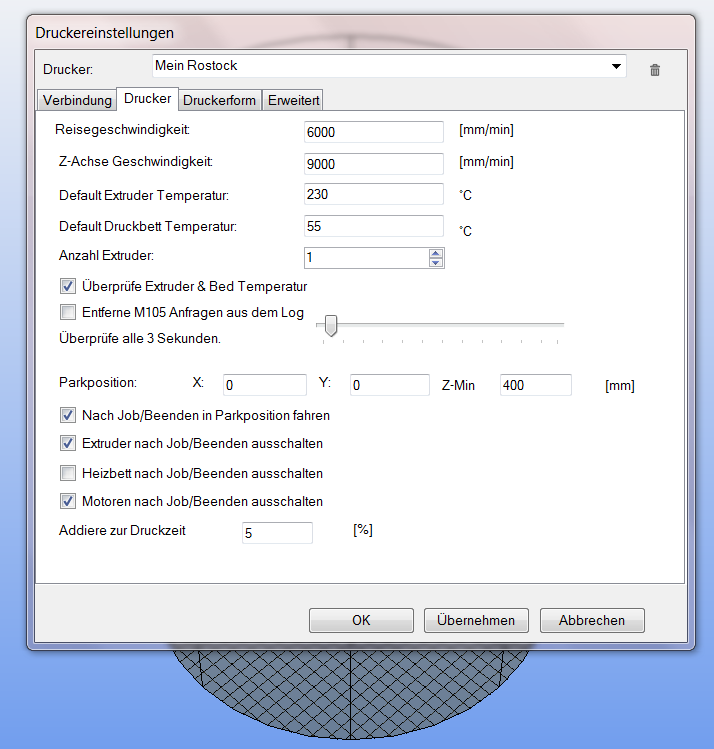

If everything is connected and you have the correct Wifi data you should be able to see Disconnect instead of Connect.Ĭlick on the Manual Control tab and you should be able to jog the Printer from the PC.Ĭourtesy of TK Ward # Maximum print speed? Change radius to 130, and height to 376.Make sure that the extruder nozzle diameter and numbers of extruders is set correctly.Change extruder temp to 270, Bed temp to 120.Click on check box for Y axis invert direction so that it is ticked.Change the IP address to the one you wrote down from your router.Click on Config then Printer settings make sure you are on the connections tab.Log on to your wifi router and get the assigned IP address for your printer, then write it down.Or use a RaspberryPi with Octoprint (opens new window) instead.QQ: See (opens new window)or see Appendix 2.You must also set Z0! Autolevel alone doesn't guarantee correct nozzle height!.In any case, you must do an autolevel at least once before doing manual leveling. Many folks say this is more accurate than autoleveling.

#Repetier server printer settings how to#

0 kommentar(er)

0 kommentar(er)